Lasers, Inc., is known for unsurpassed professional and technical services in the laser-measuring field. Lasers, Inc., is located in a suburb of Los Angeles, California. Established as a California Corporation in March of 1992. We have been in the laser measuring business since 1985 and have over 60 years of combined experience in the metrology field. We provide laser-measuring services in the United States and many other countries.

Lasers, Inc, is a SBA / SDB Certified Business as of 9/11/06.

Our

tracking number is SDB # 0306-375P.

Lasers, Inc. takes extreme pride in providing an excellent professional service to all of our clients by being prompt and reliable and straight in our communication at all times. Our technicians are among the best in the industry. We provide all information and data needed for you to make the best choices in your manufacturing process

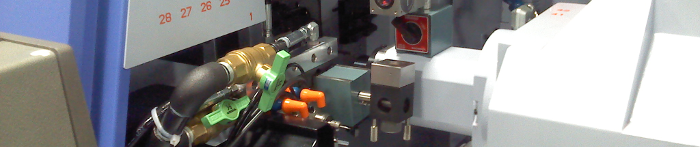

Lasers Inc. utilizes state of the art laser equipment for accurate measuring and troubleshooting expertise in numerous different manufacturing and research areas, on all types of machine tools and X-Y stages.

We provide service in several manufacturing fields and enviroments including:

- Aerospace manufacturing

- Gas and Oil Turbine manufacturing

- Gear Grinding, Hobbing, Shaping

- Tool and Die manufacturing

- Microchip and circuit board clean room enviroments

- Mold manufacturing

- Plastic injection molding machines

- Medical

- Furniture

Our service is committed to:

Increasing Profits, Precision &

Quality!

Maximizing Machine Tool Investments & Productivity!

Reducing Maintenance

& Machine Downtime!

Minimizing Programming, Editing & Inspection Time!

Decreasing

Scrap & Production Costs!

With our laser measuring and accuracy troubleshooting expertise you will enhance the performance of your Machine Tools & Robotics currently used in your manufacturing processes.

Laser Measuring and Ball-Bar testing are the most reliable and efficient techniques for machine tool calibration and trouble shooting.

- Troubleshooting Accuracy Problems on Machine Tools

- Making Rebuilding Decisions on Old Machine Tools

- Checkout & Initial Certification of New & Used Machine Tools

- Calibration & Certification of Machine Tools & currently in use

- Telescopic Ball Bar Testing for Circularity

- Measurements of Linear & Rotary Axis Positioning, Repeatability, Straightness, Flatness, Velocity, Angular Displacement (Pitch, Yaw & Roll), Level, Square and Geometrical Alignments

- Two-Axis Pivoting Heads (5-Axis Machines)

- Pitch Error & Ball-Screw Compensation Adjustments

- Backlash & Reversal Error Troubleshooting and Adjustments

- Training Courses for Laser Measuring Instruments

- Quality Control Consulting with respect to Machine Tool Accuracy

To assist you with your marketing, sales & quality control, we supply easily readable calibration reports, detailing the machine accuracy capability both before and after calibration. These reports can be submitted to your present and future customers substantiating the accuracy and capabilities in your manufacturing processes.

Lasers, Inc. provides more than just laser measuring and graph producing techniques. Our technicians go one step further and make adjustments and corrections to obtain the greatest degree of accuracy and repeatability possible on your machines.

We provide certification for your machine on an annual and semi-annual basis. Furthermore, we provide current Certification and Traceability on our testing equipment to ANSI / NCSL Z540-1-1994 (R2002). Traceability is to national standards administered by the U.S. NIST, NRC Canada, Euromet members (NPL, PTB, BNM, etc,) and other recognized standards laboratories. All of our calibration sources are ISO/IEC 17025:2005 accredited.

626.914.0716

626.914.0716 info@lasers-inc.com

info@lasers-inc.com